Exploring the Intel manufacturing environment through mixed reality

This article is contributed. See the original author and article here.

Today’s organizations have seen tremendous value in using mixed reality, as it rapidly changes how employees learn, work, and understand the world around them. With the unique value of mixed reality solutions, such as Microsoft HoloLens 2, Microsoft Dynamics 365 Guides, and Microsoft Dynamics 365 Remote Assist, organizations can drive workforce transformation with on-the-job guidance, hands-on training, and collaboration that is seamless, intuitive, and embedded into everyday workflows.

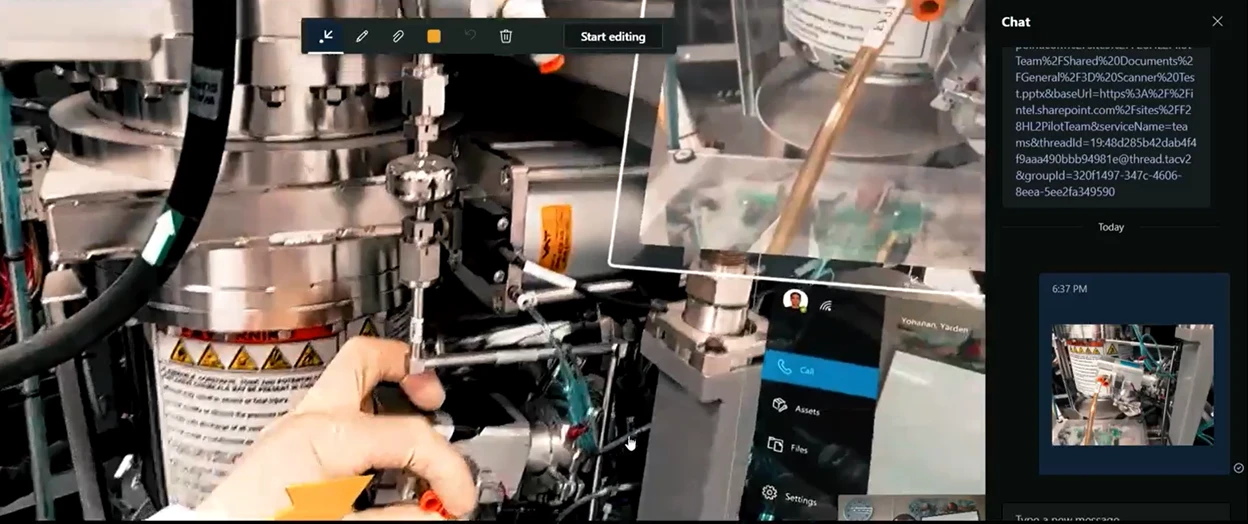

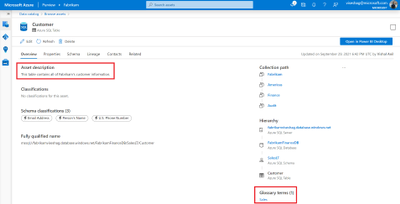

Intel technicians using HoloLens 2, Dynamics 365 Guides, and Remote Assist to resolve complex issues

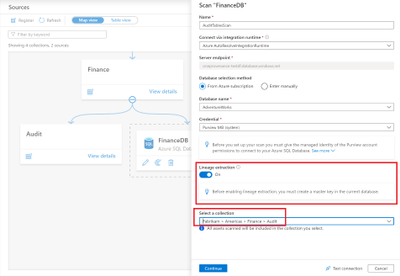

Today, we’ll look at how Intel manufacturing facilities are using mixed reality solutions such as HoloLens 2, Dynamics 365 Guides, and Dynamics 365 Remote Assist globally. In some of the world’s most advanced manufacturing facilities, technicians are responsible for building, maintaining, and troubleshooting some of the most complex manufacturing products made by humans. Working at some of the smallest known geometries, every piece of maintenance must be performed precisely by continuously improving processes to ensure the production of smarter, faster, and more energy-efficient computer chips. With six wafer fabrication sites and four assembly test manufacturing locations worldwide, Intel must maintain a global, virtual network.

In Intel’s Israel manufacturing facility, HoloLens 2 and Dynamics 365 Guides have become integral to its manufacturing processes, playing a key role in the following scenarios:

- Maintenance and repair tasks: Intel employees “learn by doing” with step-by-step instructions for conducting inspections and audits, deploying new equipment, fixing machine breaks, addressing issues faster, and increasing efficiency. Additionally, Dynamics 365 Guides allows Intel to proactively manage their assets to avoid costly downtime due to unpredicted failure. This includes conducting preventative maintenance, defining new intelligent workflows, and thoroughly completing maintenance tasks using checklists in Dynamics 365 Guides.

- Troubleshooting: Dynamics 365 Guides brings critical information into view to help Intel technicians troubleshoot, audit, or support difficult and delicate procedures, improving first-time fix rate for urgent repairs with guidance.

- Remote communication: Dynamics 365 Remote Assist seamlessly connects Intel experts and technicians through the calling feature to collaborate and solve problems without disrupting the flow of work. Dynamics 365 Remote Assist has also helped maintain the new normal to everyday routinewith advanced collaboration features, Intel has made it easy for their expert engineers to work from home to perform remote inspections that share video, screenshots, and annotations across devices. By avoiding unnecessary travel, Intel has helped increase safety and wellbeing during COVID-19 on a global scale.

- Preparing interactive training materials: Intel employees can train from home, at their desk, or on the shop floor. Dynamics 365 Guides enables authors to build digital, interactive trainings that can be viewed from anywhere and easily scale any updates to keep up with real-time changes. These trainings can be produced by anyone on a PC or HoloLens device with simple 2D and 3D creation in the real-world environment.

- Facility tour: With the power of HoloLens 2, employees can provide hands-free, digital facility tours to virtually show the inner workings of Intel’s cutting-edge facilities.

We are thrilled to see what the future holds and how mixed reality will continue to innovate manufacturing processes at Intel. To learn more, watch the video below to discover how Intel Israel is using Dynamics 365 Guides, Dynamics 365 Remote Assist, and HoloLens 2 today.

This embed requires accepting cookies from the embed’s site to view the embed. Activate the link to accept cookies and view the embedded content.

Get started with Dynamics 365 Guides

- Ready to empower your frontline employees? Read more about Dynamics 365 Guides capabilities and get your questions answered using our Dynamics 365 Guides documentation.

- Take the next step by trying a 30-day free trial of Dynamics 365 Guides.

- See how mixed reality solutions on HoloLens 2 can help your business be more productive.

- Find information on Dynamics 365 partners for manufacturing.

The post Exploring the Intel manufacturing environment through mixed reality appeared first on Microsoft Dynamics 365 Blog.

Brought to you by Dr. Ware, Microsoft Office 365 Silver Partner, Charleston SC.

Recent Comments