This article is contributed. See the original author and article here.

Today we are excited to announce the preview of our demand driven material requirements planning (DDMRP) feature for Microsoft Dynamics 365 Supply Chain Management.

The evolution of MRP

DDMRP is the next evolution of material requirements planning (MRP), which has a long and storied history in manufacturing. From its origins in the early 1960s as the first manufacturing information system, MRP’s first evolution was to MRP II during the 1980s. Then, in the 1990s, MRP II evolved further into sales and operations planning (S&OP). Most recently, MRP was extended to include major enterprise functions, forming the basis of modern enterprise resource planning (ERP) systems. As such, it is fair to say that MRP’s staying power rests in the fact that it works.

Still, almost anyone involved in manufacturing planning can tell you that while MRP works, it is far from perfect. Organizations of every industry, size, and sophistication still have items that they chronically either have too much of or, conversely, never have enough. These items drive unplanned schedule changes, create inefficiencies, and increase costs in various ways. With the arrival of DDMRP, MRP continues to add to its storied history by incorporating new innovative thinking, such as strategically decoupling inventory from the sales forecast and introducing a new calculation for lead time, that delivers significant benefits to early adopters’ organizations.

What is DDMRP?

As MRP continued to be useful, it eventually became a standard function of modern-day ERP. During this time, other significant manufacturing philosophies and methods were born. The least effective of these were fads that have faded from use, but a handful went on to transform manufacturing in their own right. These include distribution requirements planning (DRP), lean manufacturing, theory of constraints (TOC), and Six Sigma. Each of these methodologies added a tool to our belt of such significance that they remain with us and in broad use today. This brings us back to DDMRP, the newest iteration of MRP, and our latest feature available for preview. While DDMRP is a relatively new methodology, it borrows and combines elements from the tried-and-true manufacturing philosophies discussed earlier in this paragraph.

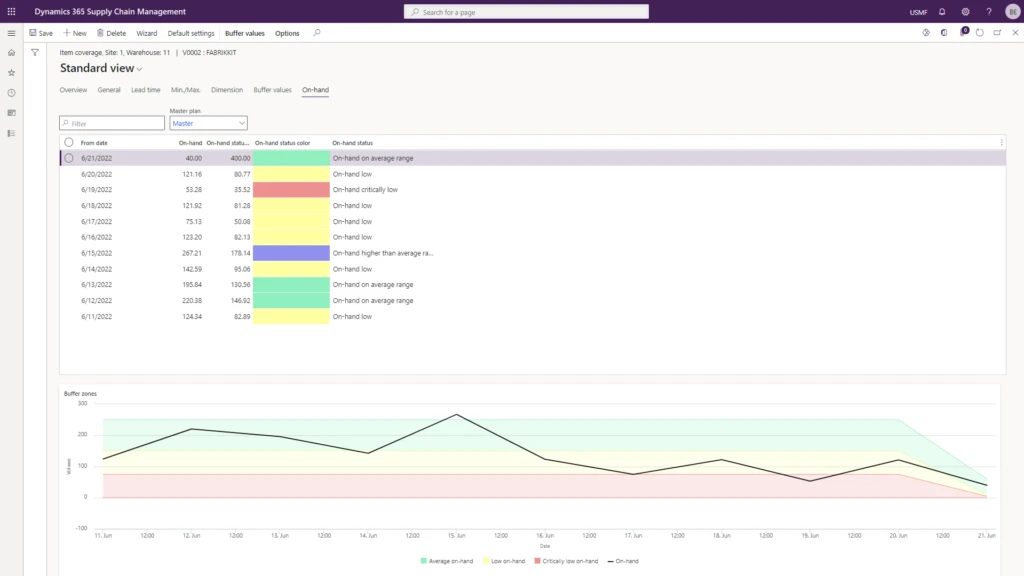

According to the Demand Driven Institute, demand driven material requirements planning (DDMRP) is “a multi-echelon planning and execution method to protect and promote the flow of relevant information through the establishment and management of strategically placed decoupling point stock buffers.”1 It is important to note that the Demand Driven Institute is essentially a standards body for all DDMRP matters. They offer certification for software vendors to ensure that the principles of DDMRP are adequately embedded and utilized in a given application, and we are proud to share that Dynamics 365 Supply Chain Management is Demand Driven Institute compliant.

Learn more about our DDMRP feature and how to enable it within supply chain management (SCM).

Benefits of using DDMRP

Several of the benefits of using DDMRP include the following:

- Improve customer service to consistently reach 97 to 100 percent on-time order fulfillment rates.

- Compress lead times for typical reductions above 80 percent across several industry segments.

- Optimize inventory to unlock inventory reductions of 30 to 45 percent without impacting service levels.

- Lower total operating costs by eliminating the false signals and schedule break-ins that drive expensive expedite activities, such as fast freight, partial ships, and cross-ships.

- Improve planner productivity by providing visibility of priorities instead of constantly fighting the conflicting messages of MRP.

Create a predictive and resilient supply chain

According to a 2022 McKinsey & Company survey of dozens of supply chain executives, 90 percent expect to overhaul planning IT within the next five years.2 The renewed focus on supply chain planning was born from a broad recognition formed during COVID-19: our modern, lean, just-in-time supply chains were amazingly efficient and cost-effective but far from resilient in the face of unprecedented and sustained global disruptions.

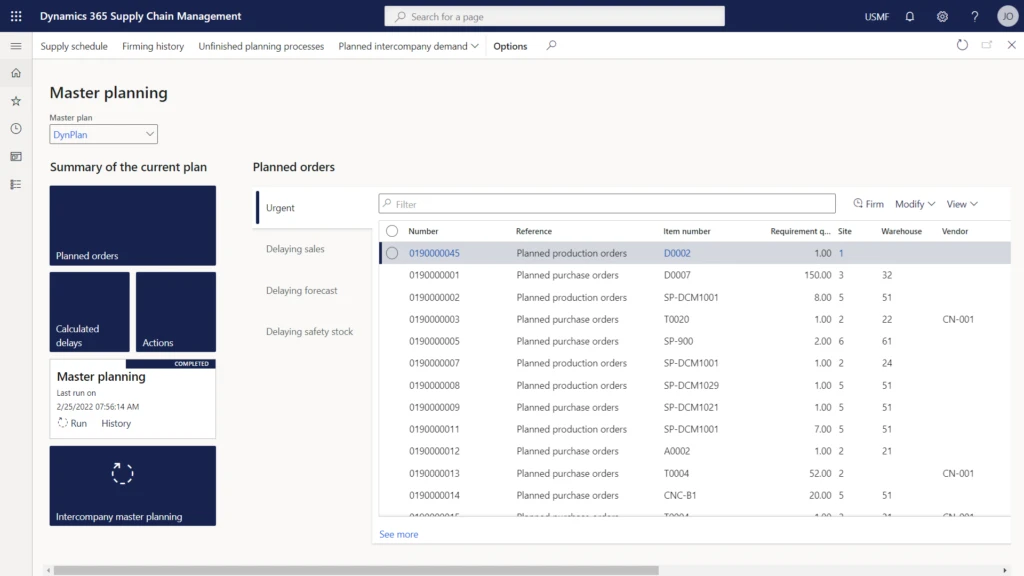

As businesses grappled with how to respond to the crisis, many identified opportunities to invest in their supply chain to become more predictive and resilient. It was no longer acceptable, as an example, for manufacturing production scheduling runs to last several hours or only run once per day. The new normal required systems to give planners near-real-time visibility and control and were capable of executing planning runs multiple times per day in the span of minutes. With our Planning Optimization Add-in, we were able to move master planning calculations outside of Dynamics 365 Supply Chain Management, which reduced planning runtimes from hours to minutes. The Planning Optimization Add-in also introduced priority-based planning, which allows businesses to distinguish demand based on urgency, and introduced one of the five steps required as part of DDMRP.

Microservices, like the Planning Optimization Add-in, are one way to quickly realize value from an ERP migration to the cloud. They deliver benefits such as better performance by offloading workloads to the cloud and improving adaptability by allowing you to react to changing demand in real-time. Ultimately, these investments in planning-related improvement features are designed to reduce stockouts and lower the cost of on-hand inventory, all while ensuring that more customer orders are fulfilled on time and in full.

Learn more in our recent blog: Optimize your supply chain with priority-based planning.

Maximize operational efficiency with agile business applications

In this blog, we announced the preview of DDMRP, reviewed the evolution of MRP, and provided a basic understanding of what DDMRP is and its benefits. Then we touched on related microservice add-ins for Dynamics 365, such as Planning Optimization and priority-based planning, which are helping organizations create predictive and resilient supply chains.

Dynamics 365 Supply Chain Management is an agile and modern, composable business application. It enables manufacturers, retailers, and distributors to create a connected and resilient supply chain by enhancing visibility, advancing planning agility, and maximizing asset uptime to operate profitably during disruptions. And for companies planning to migrate their ERP to the cloud, the composable approach of Dynamics 365 makes it easy to start with a single workload and add additional solutions as the business evolves and needs mature. It also streamlines planning, production, inventory, warehouse, and transportation to maximize operational efficiency while also giving you access to groundbreaking innovations such as demand driven material requirements planning (DDMRP).

What’s next?

Want to learn more about how your organization can use Dynamics 365 Supply Chain Management to increase production volume while reducing infrastructure costs? Check out The Total Economic Impact Of Microsoft Dynamics 365 Supply Chain Management from Forrester Consulting.

Sources

1Demand Driven Institute. What is DDMRP?

2McKinsey & Company, 2022. To improve your supply chain, modernize your supply-chain IT.

The post Strike a strategic inventory balance in your supply chain with demand driven material requirements planning (DDMRP) appeared first on Microsoft Dynamics 365 Blog.

Brought to you by Dr. Ware, Microsoft Office 365 Silver Partner, Charleston SC.

Recent Comments